After fitting up the mudsills

and mounting the hardware, Eddie Elliott and Horace Weaver set the Center

Pole in place and connect the hinge fitting.

After fitting up the mudsills

and mounting the hardware, Eddie Elliott and Horace Weaver set the Center

Pole in place and connect the hinge fitting.

After fitting up the mudsills

and mounting the hardware, Eddie Elliott and Horace Weaver set the Center

Pole in place and connect the hinge fitting.

After fitting up the mudsills

and mounting the hardware, Eddie Elliott and Horace Weaver set the Center

Pole in place and connect the hinge fitting.

When the main bearings

and hub are secured to the pole, it is lifted up into position like raising

a flag.

When the main bearings

and hub are secured to the pole, it is lifted up into position like raising

a flag.

The brace hub, sweep hub

and master gear are lowered down onto the brace pipes which form a pyramid

shape to hold most of the weight and keep the pole centered. Tommy Forney

lets the hub down as Horace and Eddie guide everything into place and lock

it down with set screws and a through pin.

The brace hub, sweep hub

and master gear are lowered down onto the brace pipes which form a pyramid

shape to hold most of the weight and keep the pole centered. Tommy Forney

lets the hub down as Horace and Eddie guide everything into place and lock

it down with set screws and a through pin.

Sweeps have been inserted

into the sockets, hung from the guy rods and cross rails installed to keep

them uniformly separated. The twelve horse cranks are installed and their

beveled gears are adjusted to the master gear with the "crow's nest bearing

assembly" which keeps the gears located and running with the proper gear

mesh. Tommy Blanton helps Eddie mount up the T-bearings on the crank shafts.

Sweeps have been inserted

into the sockets, hung from the guy rods and cross rails installed to keep

them uniformly separated. The twelve horse cranks are installed and their

beveled gears are adjusted to the master gear with the "crow's nest bearing

assembly" which keeps the gears located and running with the proper gear

mesh. Tommy Blanton helps Eddie mount up the T-bearings on the crank shafts.

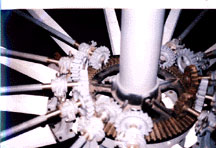

View from the top

showing the gears riding the stationary master gear. As the machine turns,

the cranks are turned...

View from the top

showing the gears riding the stationary master gear. As the machine turns,

the cranks are turned...

...and the horses ride

in the crank offsets so that they jump smoothly up and down. (Later)

...and the horses ride

in the crank offsets so that they jump smoothly up and down. (Later)

This mechanical crew is all volunteer like the painters, so give 'em a hand. And thanks to Rutherford EMC for letting Eddie bring his service truck--a BIG help. Horace and the City of Shelby play a major part, as well as lots of others who are contributing their talents.